| |

Micom

Liquid Feeder Series ¡Ð Design for Property |

| |

CS077-2 |

Operation Manual

ORP Controller |

|

| |

|

|

1.AC100 - 240V full-voltage.

2.BNC connector be suitable for every electrode.

3.A rack attached to body can be hanged on the tank.

|

| Model |

CS077-2 |

| Power

supply |

AC100V

¡ã 240V 50¡þ60 Hz |

| Measurement |

-1999mV ¡ã +1999mV

|

| Resolution |

1 mV |

| Accuracy

at 25¢XC |

¡Ó¡£0.1%+

2 digits¡¤ after calibrating |

| Impedance |

ohms ohms |

| Set

Range |

-500mV ¡ã +500mV |

| Calibration

Knob |

None external |

| Relay

Contact |

5A

for 240VAC |

| Control

Output Voltage |

Same

as plug in AC voltage |

| Display |

0.56"

LED, digits digits |

| Operating

Temperature |

0¢XC

¡ã 50¢XC ¡£32¢XF ¡ã 122¢XF¡¤ |

| Operating

Humidity |

Max.

90% |

| Power

Consumption |

Approx.

2 watts |

| Dimension |

150

x 85 x 40 mm ¡£5.9 x 3.4 x 1.6 inch¡¤ |

| Standard

Accessories |

Instruction Manual, Adjustment Sticker, Instrument Holder

each one. |

| |

|

|

ORP electrode input BNC terminal can only connect with ORP electrode, it is not allowed to connect with any other electrode. |

|

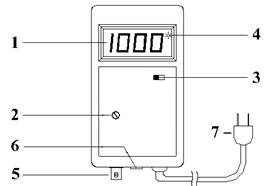

1.Display.

2.Set adjustment knob.

3.ORP¡þSET function switch.

4.Indicator of output in action.

5.Electrode BNC input terminal.

6.Control output socket ¡£Normal Open¡¤.

7.Power plug.

|

|

|

| 1. |

|

Connecting AC power supply. ¡£Make sure the correct voltage.¡¤ |

|

| 2. |

|

Connecting the ORP electrode into the ORP input terminal socket. |

|

| 3. |

|

Turn the ORP/SET switch to "ORP" position. |

|

| 4. |

|

Take away the ORP electrode from storage bottle, and clean the electrode with distilled water, then place the electrode into the water. |

|

| REMARK¡G |

|

The controller is already calibrated ¡£base on 25¢XC environment¡¤. It needs not to make calibration any more. Please contact with your dealer where you buy when the calibration is necessary to apply. |

|

|

Instruction For Cleaning & Maintenance |

|

| 1. |

|

The

immersed level for electrode should not be higher

than the electrode cap. ¡£When use the refillable

electrode, the level should be lower than filling

open to avoid the water entering into the open

and cause damage.¡¤ It had better cleaning the

ORP electrode sensor with soft brush every 2 ¡ã

3 weeks to keep the test accuracy. Please keep

the electrode in the storage bottle with 3M KCL

buffer solution; the crystallization is normal

for the keeping. |

|

| 2. |

|

ORP

electrode is accurate glass product, please do

not knock it, and do not use finger, cloth and

alcohol to clean it to avoid the damage. |

|

| 3. |

|

There

is protection "dead band" for delaying output

control in "turn on" and "turn off" to avoid frequent

switching. |

|

|

|

|

Why Shouls We Know ORP ¡£Oxidation Reduction Potential¡¤

Range |

To realize

it by easy understanding aquarium concepts, The high

or low value of ORP shows higher or lower capacity which

can oxidize toxic ammonia and nitrite in water ¡£but

also oxidize the other materials in water¡¤! In short,

more pollutants in fish tank, ORP value is relative

lower; and is often higher for less pollutant situation.

¡´A well keeping coral reef aquarium

The reference reading of ORP could be between 360 ¡£just lighted up¡¤

and 450mV ¡£duration of switching light off¡¤.

¡´A well keeping freshwater plant aquarium

The reference reading of ORP could be between 250 ¡£morning or just

turn the light up¡¤ and 400mV or even higher ¡£evening or just turn the light

off ¡¤, ¡£normally the higher ORP reading shows for lower fish population,

and the lower reading shows for higher population.¡¤

¡´The denitrifying reaction chamber or filter.

The reference reading of ORP should be between -190 and 50mV. ¡£to

avoid produce the poisonous hydrogen sulfide in over reduction, the ORP

value should not be below -190mV¡¤. |

|

The Common Situation In Higher Polluted Aquarium |

|

| The common situation is lower ORP value in higher polluted aquarium and the value is not easy to be shifted up. The common ways to take to shift the ORP value up: Use ozone generator, protein skimmer, effective trickle filter or oxygen tower to increase the dissolved oxygen in water, add additives to increase the oxidation potentials |

|

|

|

|

|